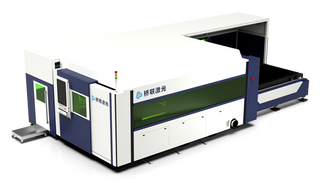

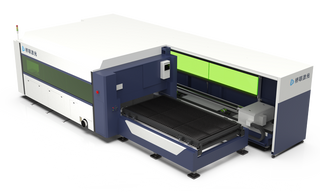

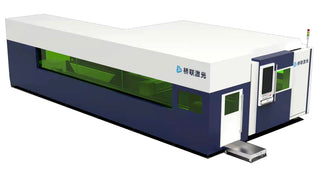

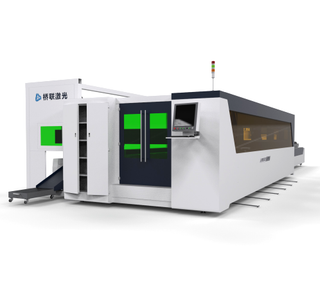

تتبنى سلسلة آلات القطع بالليزر وطاولة التبادل JLMDS غطاء حماية مغلق بالكامل ، والذي يمكن أن يلبي المتطلبات البيئية الصارمة لبعض المستخدمين. بالإضافة إلى ذلك ، يضمن تصميم التغطية الكاملة سلامة المستخدمين. أثناء العملية ، يمكن للمستخدم مراقبة عملية القطع من خلال نافذة المراقبة. بالإضافة إلى ذلك ، تم تجهيز آلة القطع بليزر الألياف ذات التغطية الكاملة بمكونات عالية الجودة لضمان دقة قطع عالية وسرعة عالية وعمر خدمة طويل. يمكن تخصيص حجم العمل وطاقة الليزر وفقًا لمتطلبات العملاء.

JLMDS Exchange Table Sheet &Tube Laser Cutting Machine Series Features

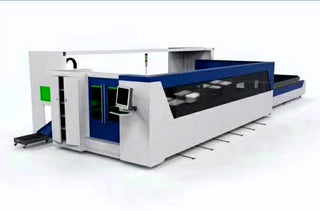

One machine can be used for both plate and pipe cutting

While improving cutting efficiency, the purchasing cost is greatly saved, and the factory can accept more diversified orders.

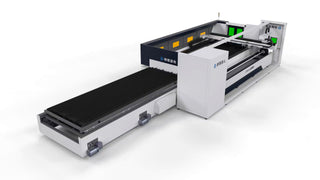

Double working table

It saves loading and unloading time. The switching platform saves space and cost.

Fully enclosed protective cover

The machine cutting area is protected by a cover to prevent spatter and improve the safety of use. Equipped with flue gas purification system, avoid environmental pollution, protect the health of operators.

Equipped with a camera

The cutting situation is clear at a glance.

JLMDS Exchange Table Sheet &Tube Laser Cutting Machine Series Advantages

Machine body is welded by thick steel plate

Adopt high quality carbon steel welding bed, more stable and durable. High strength machine tool adopts stress removal annealing treatment at 600℃, strong rigidity, small deformation, small vibration, to ensure the cutting accuracy.

Intelligent partition dust removal system

Newly upgraded intelligent partition dust removal system, dust removal design is more reasonable, effectively increase the ventilation and dust removal effect, prolong the service life of equipment.

Cast aluminum beam

The material has the characteristics of corrosion resistance, light weight and high rigidity, which ensures the high speed movement of laser processing. In addition, it also has perfect dynamic performance, such as anti-distortion, anti-overturning, anti-deformation, etc., to ensure higher cutting accuracy.

Professional tube sheet cutting system

Intelligent bus control cutting head, active collision prevention

Imported Parts, Precision Guaranteed

Equipped with Japan double high power servo motor and drive

Reducer, gear and other core transmission components are imported from Japan

High-precision rack, guide rail and ball screw are all world famous brands

Top Brand Laser Power

IPG Laser Power

Max Laser Power

Raycus Laser Power

Quality Control System

Perfect quality system, strict assembly process quality inspection, high-precision inspection equipment, to ensure that each delivered equipment can meet the company's factory quality standards.

Cutting Samples

هل لديك أي أسئلة؟ دعنا نتواصل!

اتصل بنا إذا كنت تفكر في شراء منتجات ذات جودة عالية ، أو تطوير منتجات جديدة ، أو مجرد حل مشكلة تصنيع المواد الخام الخاصة بك.