Features

Machine cutting process is totally visible. Easy to load and unload from front, left and right side.

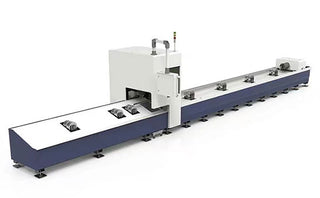

2. Advanced Appearance Design

Easy to install and quick to put into production, minimizing your waiting time for working; Designed as high-standard sealing style to prevent dust from entering in and components from being ignited.

Advantages

Steel Plate Welding Bed

1)Our machine body is welded by plate. After welding, the stress is removed by one-time quenching. After natural cooling, the rough machining is performed, then the stress is removed by two-time quenching, and after natural cooling, the finishing is performed. The equipment within 13m is integral type, and the upper gantry milling machine is processed once.

Body advantage: it is more strong and stable. Using long time, it is also have high accuracy and ensure cutting accuracy.

2)Process dust extraction experts, ship-type box design, partitioned dust extraction, more concentrated and reasonable air ducts, and better dust extraction effect;

Cast Aluminum Beam

Adopts aluminum cast beam, light weight, good dynamic response, faster acceleration and better comprehensive cutting effect;

FSCUT4000E EtherCAT Bus System

*Support basic technique of Fly cut, frog-leap lifting, kerf width compensation, lead line, micro-joint, pre-piercing, film cutting etc.

*Provide fine cutting technique, smooth start and end in the toolpath cutting.

*Support intelligent barrier avoidance, laser head frog-leap lifting in production.

*Support scan QR import drawing, task scheduling, and multi-area production etc.

*Maximum acceleration 1.5G.

*Provide dual-Y drive position error detect function.

Intelligent bus control cutting head, Active Collision Prevention

Flying cutting micro-connection, preventing sheet upwarp and realizing high speed and high stability while cutting.

Imported Parts, Precision Guaranteed

|

|

|

|||

|

Equipped with dual high-powered servo motors and drivers which from German |

Core transmission parts like speed reducer and gears are imported from Japan |

High-precision racks, guide rails and ball screws are produced by world-famous brands. |

Top Brand Laser Power

(Meet different customer needs)

|

|

|

| IPG Laser Power | Max Laser Power | Raycus Laser Power |

Quality Control System

Rigorous quality inspection of the assembly process, perfect quality system, high-precision inspection and inspection equipment: laser interferometer, laser collimator and three-coordinate projector, to ensure that each delivered customer equipment can meet the company's factory quality standards;

Cutting video

Cutting Samples

|

|

|

|

Parameters

| Model | JLM3015 | JLM4015 | JLM4020 | JLM6015 | JLM6020 |

| Power | 4000W-6000W | ||||

| Working Area (L*W) | 3000*1500mm | 4000*1500mm | 4000*2000mm | 6000*1500mm | 6000*2000mm |

| X/Y-axis Positioning Accuracy | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm |

| X/Y-axis Repositioning Accuracy | ±0.01mm | ±0.01mm | ±0.01mm | ±0.01mm | ±0.01mm |

| Max. No-load Speed | 100m/min | 100m/min | 100m/min | 100m/min | 100m/min |

| Max. Acceleration | 1G | 1G | 1G | 1G | 1G |

*The above data are for reference only, subject to the actual product!

Related Product

Have any questions?Let's get in touch!

Contact us if your are thinking of purchasing highqualityingredients, develop new products, or justsolving a manufacturing challenge in your rawmaterials.