I.Robot Welding Description:

2.Wide working area, capable of welding various long and curved welds;

3.Single robot collaborative operation effectively improves welding efficiency, reduces welding deformation, and ensures welding quality;

4.By cooperating with the gantry walking track, it is possible to achieve simultaneous welding and handling of workpieces, thereby improving production efficiency.

5.The software can be operated in a foolproof manner after 1-2 days of training, and there is no need for manual intervention throughout the entire process after loading, greatly reducing the skill requirements for operators.

II.Robot Welding Parameters:

| Content | Parameter Range | Unit | Remarks |

| Degrees of Freedom (Axes) | 9 | / | / |

| Required Ambient Temperature | -10~45 | ºC | / |

| Maximum End Load | 6 | Kg | / |

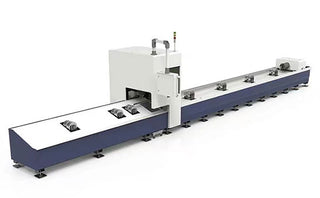

| Recommended Floor Space | W8000*L20000*H2000 | mm | / |

| Peak Total Power | 60 | kW | / |

| Rated Input Voltage/Frequency | 380+/-10% | V | Three-phase |

| Rated Input Frequency | 50 | Hz | / |

| Floor Space | 10000*22000 | mm | / |

III. Robot Welding Advantages:

|

Robot Integrated Drive and Control System

4. Equipped with collision detection and monitoring. |

Digital Twin System

2. Operation through the computer interface, with the physical object following movements. 3. Scene-generated trajectory, one-click command, and welding can begin. 4. Real-time communication, integration of virtual and physical, command execution. |

|

|

No-Teaching, No-Programming

2. Process Commands · Rapid Deployment: Corner welds, intermittent welding, multi-layer and multi-pass commands can be selected with one click. 3. Vision Guidance · Automatic Path Planning: Using line laser scanning, the robot quickly locates the start and end positions of the welding seam. |

Built-in Welding Process Library

2. Weld Seam Editing: Select weld edges to batch-generate weld seams, break over weld holes, and continuously weld edges. Choose welding processes according to the weld seam (multi-layer and multi-pass, upward vertical corner weld). 3. Simulation Check: Verify whether the running trajectory is reasonable, or if there is any interference. Ensure that the welding angle satisfies the welding process. |

|

|

Visual Positioning and Tracking Module

(2). Accurately reflects the position and posture of the workpiece, with image capture to result output time being less than one second. (3). Precise positioning prevents collisions during the welding process. (4). Full graphical interface operation-no prior robot operation experience required, easily completing the entire workflow. |

IV. Welding Robot Weld Type

V.Robot Welding Samples

Related Product

Have any questions?Let's get in touch!

Contact us if your are thinking of purchasing highqualityingredients, develop new products, or justsolving a manufacturing challenge in your rawmaterials.