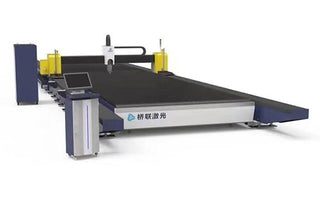

La série de machines de découpe laser à portique grand format JLH est un type d'équipement de découpe laser principalement utilisé pour couper des matériaux métalliques, tels que l'acier au carbone, l'acier au silicium, l'acier inoxydable, l'alliage d'aluminium, l'alliage de titane, la tôle galvanisée, le cuivre, et autres matériaux métalliques. Il a une large gamme d'applications dans diverses industries de fabrication et de transformation, telles que le traitement de la tôle, l'aérospatiale, les appareils électriques, les automobiles, les machines, les navires, les équipements métallurgiques, les ascenseurs, les appareils électroménagers, la publicité et le traitement externe des métaux.

JLH Large Format Gantry Laser Cutting Machine Series Features

- Large format gantry fiber laser cutting machine It is suitable for high-power laser cutting of medium and heavy plates. The laser selection range is 6000W-40000W. Long-term batch cutting of 6-50MM plates.

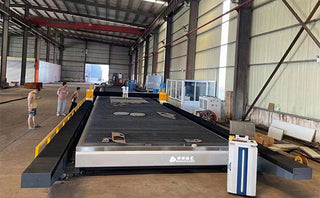

- Large format, wider range of format processing options Width: 2500-5000mm, length: 8000-26000mm.

- Segmented spliced bed structure

- Segmented spliced bed structure The length of the segmented bed can be customized. Modular installation, efficient and convenient. The separation structure of the material table and the bed is more suitable for thick plate cutting without heat transfer.

- Perfect dust removal and environmental protection system Segmented double suction dust removal design structure, hurricane suction, strong negative pressure, let dust and smoke move with the wind. Within a range of 1 meter, always keep the air door in one area open to vacuum, and the air door in other areas is closed, the wind is strong, and the dust removal is smooth and clean.

- Bevel function Cut V/A/X/Y/K bevels.

Advantages of JLH Format Gantry Laser Cutting Machine Series

Steel Plate Welding Bed

The Qiaolian metal laser cutter body is welded by sheet metal, the equipment within 13m is integral, and the upper gantry milling machine is processed at one time. Body advantage: more sturdy and stable. Long use time to ensure cutting accuracy.

Cast Aluminum Beam

It adopts aluminum cast beam, which is light weight, good dynamic response, faster acceleration and better comprehensive cutting effect.

High-end Intelligent EtherCAT Bus System

Specially designed for ultra-high power metal laser cutting machines above 8KW, FSCUT8000 is an EtherCAT bus system. It has the characteristics of out-of-the-box, easy installation and adjustment, and complete functions. It supports customization, automation and information solutions and is the market-leading EtherCAT laser cutting control system.

Intelligent bus control cutting head, Active Collision Prevention

The focus can be adjusted according to the thickness of the material, which is suitable for multi-focal lengths. It can reduce punching time, improve punching quality, and can sense the surrounding environment and intelligently lift and avoid obstacles.

It adopts flying-cut micro-connection to prevent sheet warping. It can also achieve high speed and high stability during cutting.

Vous avez des questions ? Contactez-nous !

Contactez-nous si vous envisagez d'acheter des ingrédients de haute qualité, de développer de nouveaux produits ou simplement de résoudre un problème de fabrication dans vos matières premières.