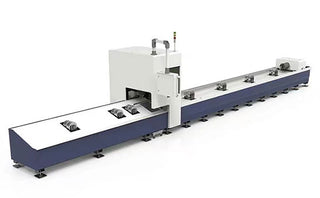

3D Tube Laser Cutting Machine

Features

1. 3-chuck Clamping Technology

2.Real 0 tailing without tube length restriction

3. 3D bevel cutting process saves 20-30% time,

4.Cut 12000mm entire tube at most

5.Maximum pipe diameter 450

6.Maximize the weight of single tube

6.Maximize the weight of single tube

7.Cover can be optional.

8.Automatic uploading can be optional

Advantages

Multi-point Supporting for Heavy Tubes

Tubes are usually clamped and supported by three chucks concurrently. Any tube deformation can be automatically corrected to keep cutting precision high and cutting products of uniform size.

EtherCAT bus system

FSCUT5000 series is EtherCAT bus system specially designed for fiber laser tube cutting machine. Work with TubesT 3D nesting software, it will achieve most efficiency and minimum waste.

Auto Focus Laser Cutting Head

The product is equipped with slender TRA components and slender nozzles, which can adapt to any complex tube cutting and cutting product conditions, and has a built-in motor drive unit, which drives the focusing mirror to automatically change its position within a certain range through a linear mechanism. It can realize continuous focusing, complete rapid perforation and automatic cutting of pipes of different thicknesses and materials; the optimized optical and water-cooled design enables the laser head to work continuously and stably for a long time.

Perform Well in Tube Cutting

Cut max. 12000mm entire tube

Max. cutting range of round tube Φ20-450mm

Also cut profiles like channel, angle and I-shaped steel etc.

Max. cutting range of round tube Φ20-450mm

Also cut profiles like channel, angle and I-shaped steel etc.

Imported Parts, Precision Guaranteed

|

|

|

|||

|

Equipped with dual high-powered servo motors and drivers which from German |

Core transmission parts like speed reducer and gears are imported from Japan |

High-precision racks, guide rails and ball screws are produced by world-famous brands. |

Top Brand Laser Power

(Meet different customer needs)

|

|

|

| IPG Laser Power | Max Laser Power | Raycus Laser Power |

Quality Control System

Rigorous quality inspection of the assembly process, perfect quality system, high-precision inspection and inspection equipment: laser interferometer, laser collimator and three-coordinate projector, to ensure that each delivered customer equipment can meet the company's factory quality standards;

Cutting video

Laser Tube Machine Cutting Samples

|

|

|

|

Steel Tube Laser Cutting Machine Parameters

|

Model

|

JCT3612

|

JCT3616

|

JCT3622

|

JCT3628

|

JCT3632

|

JCT3635

|

JCT3645

|

|

Power

|

1000W-6000W

|

||||||

|

Min.Dia(mm)

|

20

|

20

|

20

|

20

|

20

|

20

|

20

|

|

Max.Dia(mm)

|

120

|

160

|

220

|

280

|

320

|

350

|

450

|

|

Tube length(mm)

|

3000 / 6000 / 9000 / 12000

|

||||||

|

Maximum revolutions of chuck(RPM)

|

80-120

|

||||||

|

X/Y-axis Positioning Accuracy

|

±0.05mm

|

±0.05mm

|

±0.05mm

|

±0.05mm

|

±0.05mm

|

±0.05mm

|

±0.05mm

|

|

X/Y-axis Repositioning Accuracy

|

±0.03mm

|

±0.03mm

|

±0.03mm

|

±0.03mm

|

±0.03mm

|

±0.03mm

|

±0.03mm

|

|

Positioning speed

|

90m/min

|

90m/min

|

90m/min

|

90m/min

|

90m/min

|

90m/min

|

90m/min

|

|

Max. Acceleration

|

1G

|

1G

|

1G

|

1G

|

1G

|

1G

|

1G |

*The above data are for reference only, subject to the actual product!

Related Product

Have any questions?Let's get in touch!

Contact us if your are thinking of purchasing highqualityingredients, develop new products, or justsolving a manufacturing challenge in your rawmaterials.