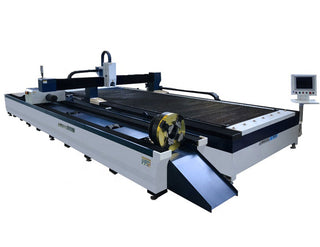

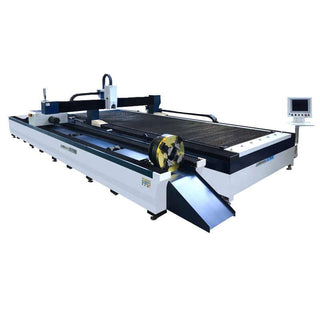

JLNS シングルシートおよびチューブレーザー切断機は、コスト効率の高い機械です。この機械は金属シートとチューブを切断できるため、プロ仕様のシート レーザー カッターやチューブ レーザー カッターの理想的な代替品となります。この機械は、使いやすいオープン構造と高度な外観デザインを採用しており、設置が早く、生産を簡単に開始でき、オペレーターが材料をロードおよびアンロードするのに便利です。

単板パイプレーザー切断機は、効率的で正確かつ便利なツールであり、産業発展の分野では避けられない傾向でもあります。約 20 年にわたる産業発展を経て、金属製造の分野で不可欠なツールに発展しました。

JLNS High Power Single Table Sheet & Tube Laser Cutting Machine Series Features

One Machine With Two Functions

This machine can cut metal sheets and pipes, it is a combination of professional sheet laser cutting machine and pipe laser cutting machine. For users, it expands the range of cutting materials and improves market competitiveness.

Open-type Structure

The machine cutting process is fully visible. Operators can easily load and unload from the front, left and right sides.

Advanced Appearance Design

The machine is easy to install and quick to put into production, which minimizes your waiting time for installation. High standard sealed design prevents dust from entering and parts from igniting. The cutting tube is separated from the plate, and the cutting precision is high.

JLNS High Power Single Table Sheet & Tube Laser Cutting Machine Series Advantages

JLNS High Power Single Table Sheet & Tube Laser Cutting Machine Series Advantages

The body of the machine is welded from plates. After two quenching to eliminate the stress, making the body stronger and more stable. Long service time, high precision, to ensure the cutting accuracy. Within 13m, the equipment is integral and the upper gantry milling is processed once.

It adopts ship type box design, partition dust removal, more concentrated and reasonable air duct, dust removal effect is better.

Cast Aluminum Beam

Aluminum cast beam, light weight, good dynamic response, fast acceleration, good comprehensive cutting effect.

Professional tube sheet cutting system

Auto Focus Laser Cutting Head, Active Collision Prevention

The machine can adjust the focus according to the thickness of the material, suitable for a variety of focal segments, reduce punching time, improve punching quality. It can also sense its surroundings and intelligently raise its head to avoid obstacles. Fly-cut micro connection prevents sheet warping, achieving high speed and high stability when cutting.

ご質問がございましたら、お気軽にお問い合わせください。

高品質の原材料の購入、新製品の開発、または原材料の製造上の課題の解決をお考えの場合は、お問い合わせください。