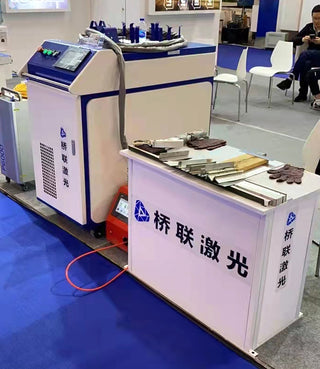

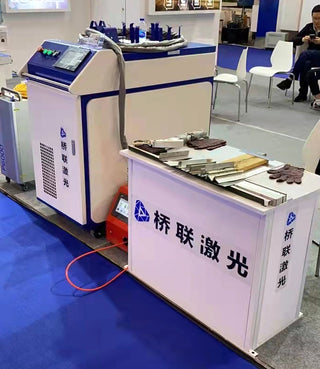

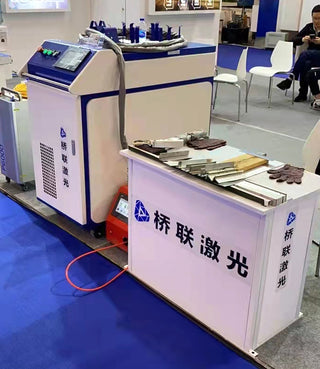

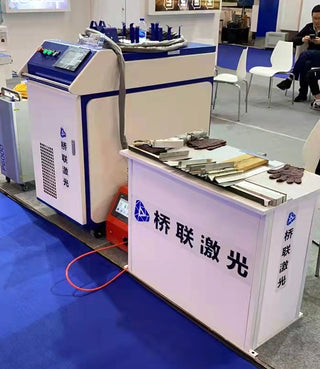

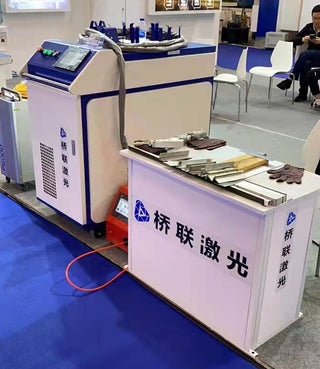

この手持ち式ファイバー レーザー溶接機はあらゆる部品の溶接に最適で、移動も簡単です。新しいデュアル スキャン テクノロジーが搭載されており、当社の新しい軽量ピストルはさまざまな種類の溶接を実行できます。さらに、当社のワンショット溶接による形状プロセスにより、歪みがないため、製品は期待される高品質基準を満たします。

簡単な操作、安定した動作、完璧な溶接ビーム、速い溶接速度という利点があります。この機械は、薄いアルミニウム板、ステンレス鋼板、鉄板、亜鉛メッキ板などの金属材料の溶接に適しています。従来のアルゴンアーク溶接やミグ溶接プロセスを完全に置き換えることができます。高出力と高速溶接速度により、大量生産に最適です。

手持ち式レーザー溶接機は、キャビネット、キッチン、階段、エレベーター、収納ラック、オーブン、ステンレス鋼のドアと窓のガードレール、配電ボックス、ステンレス鋼の家庭用およびその他の産業における複雑で不規則な溶接プロセスに広く使用できます。

1000W to 3000W Handheld Fiber Laser Welding Machine Features

1000W to 3000W Handheld Fiber Laser Welding Machine Advantages

Suitable for different scenes with 6 luminous modes.

Light spot is adjustable from 0 to 6 mm.

Directly set the parameters of wire feeder digitally through the control screen, keeping the wire feeding smoothly.

Stainless steel, carbon steel and aluminum wire can be delivered in various (0.8\1.0\1.2\1.6mm) specifications.

Perfect replacement part of the traditional argon arc welding, thin stainless steel plate, iron plate, aluminum plate and other electric welding.

Weld penetration table

| Material | Thickness (mm) |

Wire feed speed (mm/s) |

scan width (mm) |

Power (W) |

wire diameter (mm) |

Max Weld penetration | Using Gas |

| Stainless steel | 1 | 80 | 2.5 | 350 | ER304 1.0 | 90% | Nitrogen/ argon |

| 2 | 80 | 3 | 500 | ER304 1.2 | 100% | ||

| 3 | 70 | 3 | 700 | ER304 1.2 | 100% | ||

| 4 | 65 | 3.5 | 1000 | ER304 1.2 | 100% | ||

| 5 | 60 | 3.5 | 1500 | ER304 1.6 | 100% | ||

| 6 | 60 | 4 | 1600 | ER304 1.6 | 80% | ||

| 7 | 60 | 3.5 | 2000 | ER304 1.6 | 100% | ||

| 8 | 50 | 3.5 | 2800 | ER304 1.6 | 100% | ||

| Carbon steel | 0.5 | 45 | 2.5 | 250 | ER 0.8 | 80% | Nitrogen/ argon/pure air |

| 1 | 80 | 2.5 | 380 | ER 1.0 | 90% | ||

| 2 | 70 | 3 | 700 | ER 1.2 | 100% | ||

| 3 | 65 | 3 | 1200 | ER 1.2 | 100% | ||

| 4 | 60 | 3.5 | 1500 | ER 1.2 | 100% | ||

| 5 | 60 | 3.5 | 1700 | ER 1.6 | 100% | ||

| 6 | 60 | 4 | 2000 | ER 1.6 | 80% | ||

| 7 | 50 | 3.5 | 2600 | ER 1.6 | 100% | ||

| 8 | 45 | 3.5 | 3000 | ER 1.6 | 100% | ||

| Aluminium | 1 | 80 | 2.5 | 450 | AL 1.0 | 90% | Nitrogen/ argon |

| 2 | 70 | 3 | 900 | AL 1.2 | 100% | ||

| 3 | 65 | 3 | 1500 | AL 1.2 | 100% | ||

| 4 | 60 | 3.5 | 1800 | AL 1.2 | 100% | ||

| 5 | 60 | 3.5 | 2200 | AL 1.6 | 100% | ||

| 6 | 55 | 3.5 | 2800 | AL 1.6 | 80% | ||

| Note: 1.Default parameters: scanning speed: 300mm, duty cycle: 100%, pulse frequency: 1000Hz 2.The above gas welding blowing pressure is set between 0.3 MPa and 0.5 MPa by adjusting the pressure regulating valve 3.Suggest gas using Nitrogen, Nitrogen purity:99.99% |

|||||||

Imported Parts, Precision Guaranteed

Welding type:

Fillet welding vertical welding

Tailor welding flat welding

Overlap welding

Samples

ご質問がございましたら、お気軽にお問い合わせください。

高品質の原材料の購入、新製品の開発、または原材料の製造上の課題の解決をお考えの場合は、お問い合わせください。