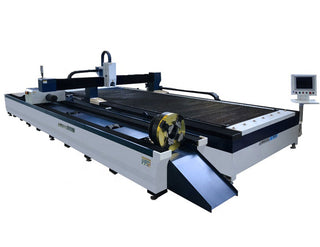

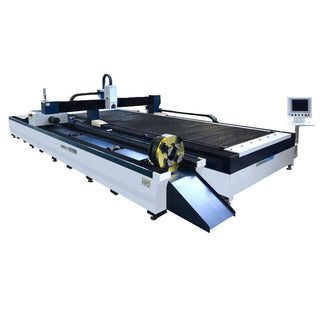

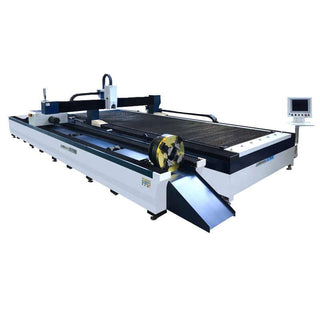

JLNS 단일 시트 및 튜브 레이저 절단기는 비용 효율적인 기계입니다. 이 기계는 시트 및 튜브 금속을 절단할 수 있으므로 전문 시트 레이저 절단기 및 튜브 레이저 절단기를 이상적으로 대체할 수 있습니다. 이 기계는 사용하기 쉬운 개방형 구조와 고급 외관 디자인을 채택하여 설치가 빠르고 생산에 투입하기 쉬우며 작업자가 자재를 싣고 내리는 데 편리합니다.

단일 파이프 레이저 절단기는 효율적이고 정확하며 편리한 도구이며 산업 발전 분야에서 불가피한 추세입니다. 거의 20년에 가까운 산업 발전 끝에 금속 제조 분야에서 없어서는 안 될 도구로 발전했습니다.

JLNS High Power Single Table Sheet & Tube Laser Cutting Machine Series Features

One Machine With Two Functions

This machine can cut metal sheets and pipes, it is a combination of professional sheet laser cutting machine and pipe laser cutting machine. For users, it expands the range of cutting materials and improves market competitiveness.

Open-type Structure

The machine cutting process is fully visible. Operators can easily load and unload from the front, left and right sides.

Advanced Appearance Design

The machine is easy to install and quick to put into production, which minimizes your waiting time for installation. High standard sealed design prevents dust from entering and parts from igniting. The cutting tube is separated from the plate, and the cutting precision is high.

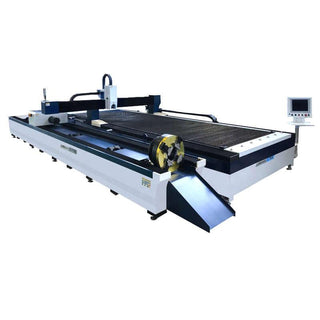

JLNS High Power Single Table Sheet & Tube Laser Cutting Machine Series Advantages

JLNS High Power Single Table Sheet & Tube Laser Cutting Machine Series Advantages

The body of the machine is welded from plates. After two quenching to eliminate the stress, making the body stronger and more stable. Long service time, high precision, to ensure the cutting accuracy. Within 13m, the equipment is integral and the upper gantry milling is processed once.

It adopts ship type box design, partition dust removal, more concentrated and reasonable air duct, dust removal effect is better.

Cast Aluminum Beam

Aluminum cast beam, light weight, good dynamic response, fast acceleration, good comprehensive cutting effect.

Professional tube sheet cutting system

Auto Focus Laser Cutting Head, Active Collision Prevention

The machine can adjust the focus according to the thickness of the material, suitable for a variety of focal segments, reduce punching time, improve punching quality. It can also sense its surroundings and intelligently raise its head to avoid obstacles. Fly-cut micro connection prevents sheet warping, achieving high speed and high stability when cutting.

질문이 있으십니까?연락합시다!

고품질 재료 구매, 신제품 개발 또는 원자재의 제조 문제 해결을 생각하고 있다면 저희에게 연락하십시오.