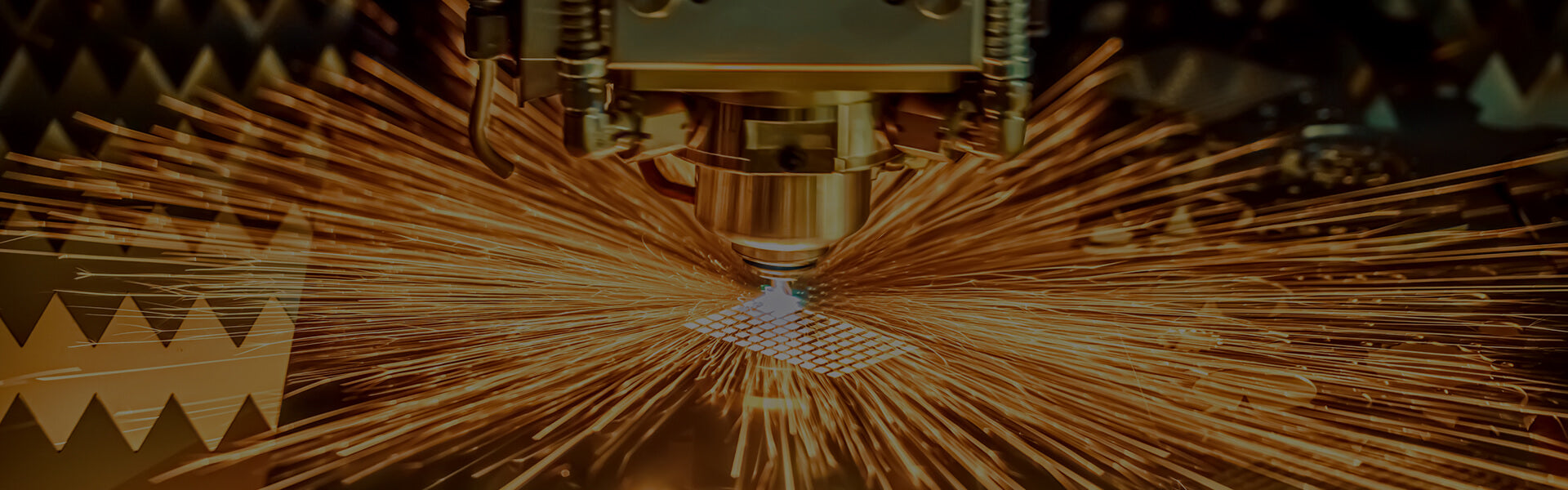

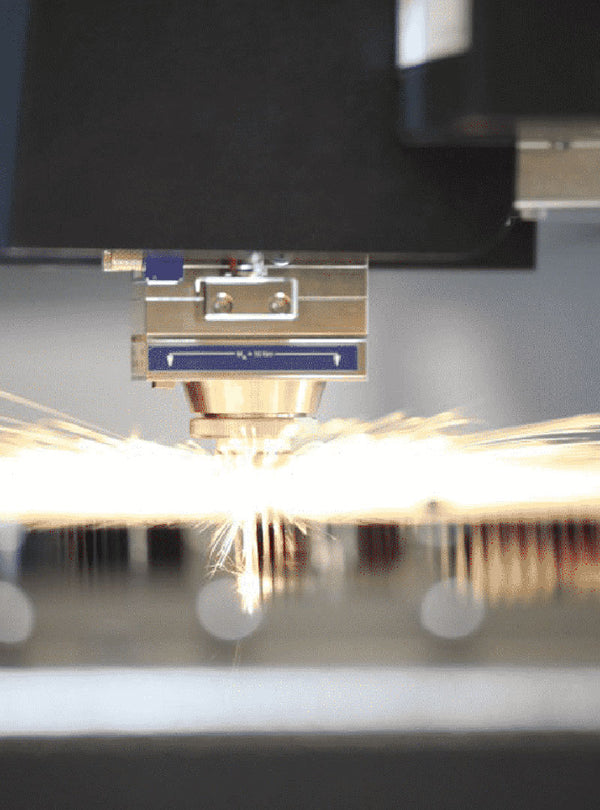

The aerospace industry demands the highest standards in terms of precision, reliability, and efficiency. One of the most cutting-edge technologies that has emerged in recent years to meet these requirements is the fiber laser. Fiber lasers are a type of laser that use optical fibers to amplify and guide light waves, resulting in a highly efficient and effective beam of light. In the aerospace industry, fiber lasers are used for a variety of applications, including cutting, welding, and surface treatment of materials such as aluminum, titanium, and carbon fiber composites.

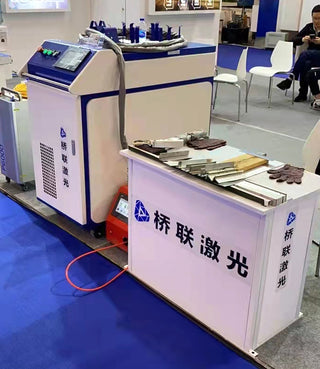

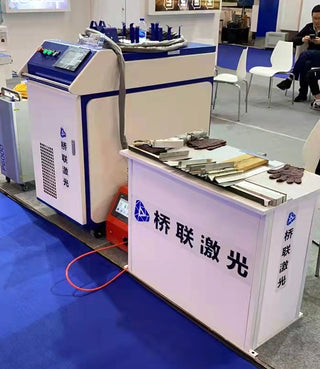

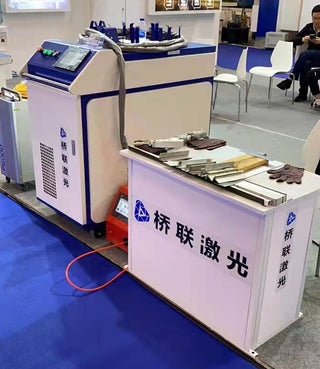

Compared to traditional laser sources, fiber lasers offer many advantages. They are smaller in size, require less maintenance, and have a longer lifespan. They can also produce a higher power output, allowing for faster and more precise processing of materials.

For the aerospace industry, where every millimeter and every gram of weight counts, the use of fiber lasers has significant implications. They enable manufacturers to produce lighter and stronger components, resulting in more efficient and reliable aircraft.

At its core, the fiber laser is a technology that has revolutionized how we process materials, and its impact on the aerospace industry has been profound. As technology continues to evolve, we can expect to see even more innovative uses of fiber lasers in aerospace manufacturing.