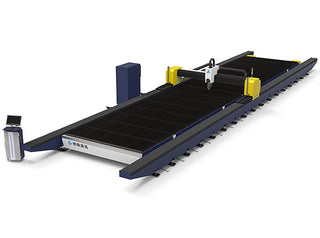

Introduction A tube laser cutting machine is a specialized piece of equipment designed to cut, engrave, or process metal tubes and profiles with exceptional precision. Unlike traditional flat sheet laser cutters, tube laser cutting machines are engineered to handle cylindrical, rectangular, and other shaped tubes, making them indispensable in industries that require complex cuts on tubular...

Nachricht

Precision and Efficiency: Why Metal Laser Cutting is Revolutionizing Manufacturing

Introduction In the world of modern manufacturing, metal laser cutting has emerged as a revolutionary technology, offering unmatched precision and efficiency. From automotive to aerospace, industries are leveraging this advanced technology to improve productivity, reduce costs, and deliver high-quality products. In this blog, we’ll explore why metal laser cutting is transforming manufacturing and how it can benefit your business. For...

How to Choose the Best Metal Laser Cutting Machine for Your Needs

Introduction Choosing the best metal laser cutting machine for your business is a critical decision that can significantly impact your productivity and profitability. With so many options available, it’s essential to consider factors like material type, cutting speed, budget, machine size, and gas selection for different thicknesses. In this guide, we’ll walk you through the key steps to...

CO2 vs. Fiber Laser Cutting Machines: Which One is Right for You?

Introduction When it comes to laser cutting machines, two of the most popular options are CO2 lasers and fiber lasers. Both technologies have their unique strengths and are suited for different applications. But how do you decide which one is right for your business? In this blog, we’ll compare CO2 vs. fiber laser cutting machines to...

Applications of Laser Cutting Technology

Introduction Laser cutting technology has revolutionized modern manufacturing, offering unparalleled precision, speed, and versatility. From automotive to aerospace, this technology is transforming how industries operate. In this blog, we’ll explore the diverse applications of laser cutting technology and how it’s driving innovation across various sectors. For more insights, check out our blog on Top 10 Benefits of...

Laser Cutting Maintenance Tips

Introduction Regular maintenance is crucial to keep your laser cutting machine running smoothly and efficiently. Proper care not only extends the lifespan of your machine but also ensures consistent performance and high-quality cuts. Neglecting maintenance can lead to costly repairs, downtime, and reduced productivity. In this blog, we’ll share essential laser cutting maintenance...

Stichworte:Laser Cutting Maintenance Tips

Top 10 Benefits of Using a Metal Laser Cutting Machine for Your Business

Introduction In today’s competitive manufacturing landscape, businesses are constantly seeking ways to improve efficiency, reduce costs, and deliver high-quality products. One technology that has revolutionized the industry is the metal laser cutting machine. From automotive to aerospace, these machines are transforming how businesses operate. In this blog, we’ll explore the top 10...

Future Trends in Laser Cutting Technology

Introduction The laser cutting industry is evolving rapidly, driven by advancements in technology and changing market demands. From automation to sustainability, these trends are shaping the future of manufacturing. In this blog, we’ll explore the future trends in laser cutting technology and how they’re transforming the industry. For more insights, check out our blog on Top 10 Benefits...

How to Choose the Right Laser Cutting Machine

Introduction Choosing the right laser cutting machine is a critical decision for any business. With so many options available, it can be overwhelming to determine which machine best suits your needs. Whether you're cutting steel, stainless steel, aluminum, or non-metallic materials, selecting the right machine can significantly impact your productivity and profitability. In this guide,...

The Ultimate Guide to Metal Laser Cutting Machines (Part 2)

Introduction In Part 1 of this guide, we explored how metal laser cutting machines work, their types, and why they’re essential for modern manufacturing. In Part 2, we’ll dive deeper into their applications, maintenance tips, future trends, and FAQs to help you make the most of this transformative technology. 1. Applications of Metal Laser Cutting Machines Metal laser cutting...

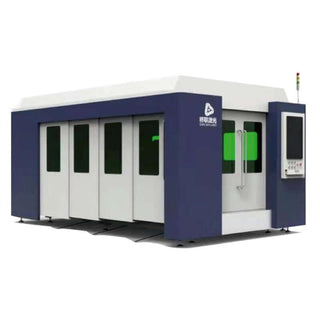

The Ultimate Guide to Metal Laser Cutting Machines (Part 1)

Introduction Metal laser cutting machines have revolutionized the manufacturing and fabrication industries. With their unparalleled precision, speed, and versatility, they are a must-have tool for businesses looking to stay competitive. In Part 1 of this ultimate guide, we’ll explore how metal laser cutting machines work, the types of machines available, and why you need one for...

Understanding Metal Fiber Laser Cutting Machine Cut Thickness: A Comprehensive Guide

I. Introduction to Fiber Laser Cutting Technology Fiber Laser Cutting: The Advanced Solution for Precision Metal Cutting Fiber laser cutting is a cutting-edge technology that has revolutionized the way metals and other materials are cut. Utilizing a high-powered laser beam generated by a fiber laser source, this method delivers unmatched precision, speed, and efficiency. The laser beam is...

2025 Qiaolian Laser Annual Meeting

We are delighted to celebrate the successful conclusion of our annual meeting, held on January 18, 2025. We extend our heartfelt wishes to all our new and longstanding friends for good health, joyful family moments, and continued success in their professional endeavors throughout the new year!

The world's first 160kW ultra-high power fiber laser from MAX Laser has been released

The world's first 160kW ultra-high power fiber laser from MAX Laser has been released On July 17, MAX Laser officially launched the world’s first 160kW ultra-high-power industrial fiber laser in Shenzhen. This groundbreaking achievement not only sets a new global record for the highest power of fiber lasers but also...

Laser Cutting Machine Consumables

Laser Head Brands and Consumables 1. BOCI Protective Lenses: Lens Diameter: 1.5 inches, Part Number: BOCI-LENS-150 Lens Diameter: 2.0 inches, Part Number: BOCI-LENS-200 Nozzles: Single-Layer Nozzle, Diameter: 1.0 mm, Part Number: BOCI-NOZZLE-10 Double-Layer Nozzle, Diameter: 1.5 mm, Part Number: BOCI-NOZZLE-15 Ceramic Rings: Part Number: BOCI-CERAMIC-20 Fiber Cables: Model: BOCI-FIBER-10M (10...

Laser Machines and Processing Systems

1. Principles of Laser Generation 1.1 Principle of Laser Generation The atomic structure resembles a miniature solar system, with the nucleus at the center and electrons continuously orbiting around it, while the nucleus also rotates. The nucleus consists of protons and neutrons; protons are positively charged, and neutrons are...