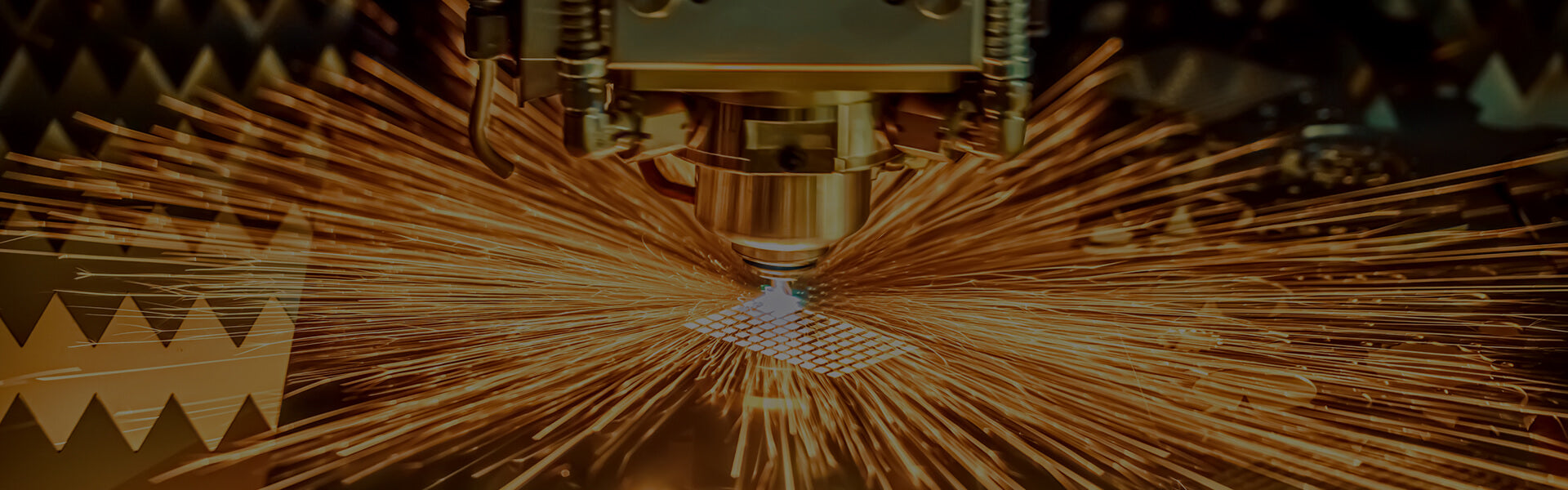

The increasing progress of fitness machinery and equipment requires higher precision machining of its parts. Factors such as the width of the part kerf, the straightness of the edge, the fineness of the stripes, and the smoothness of the part all significantly affect the quality of the fitness equipment. Given the variety of shapes of fitness equipment parts, fully automatic CNC laser cutting equipment goes beyond traditional processing methods and effectively meets the needs of modern machines.

To achieve the best results in fitness equipment production, precise and efficient manufacturing processes must be followed. Traditionally, this required cutting the pipe and then drilling holes in the pipe using a band saw drill and a specialized milling machine. However, this approach often falls short in terms of aesthetics and accuracy. In addition, workpiece clamping and transfer require a lot of labor costs and time.

With its high flexibility and high efficiency, the laser tube cutting machine has greatly improved the production process in the fitness equipment industry. Manufacturers can experience increased productivity and reduced cycle times by utilizing fully automated machining methods. This makes the laser tube cutting machine an essential equipment in the fitness equipment manufacturing process.

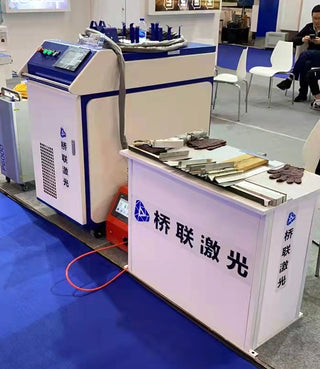

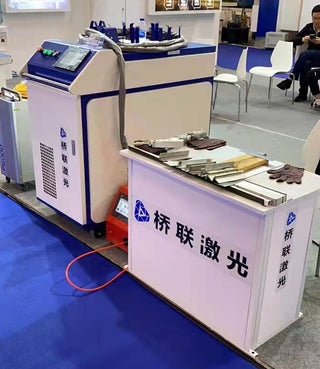

In addition, the fiber laser cutting machine also has the characteristics of high output per unit time and less waste residue. It offers exceptional stability and durability while also offering automatic tying and loading. Thanks to its built-in robotic capabilities, it eliminates the need for labor-intensive tasks that require enormous strength and stamina.