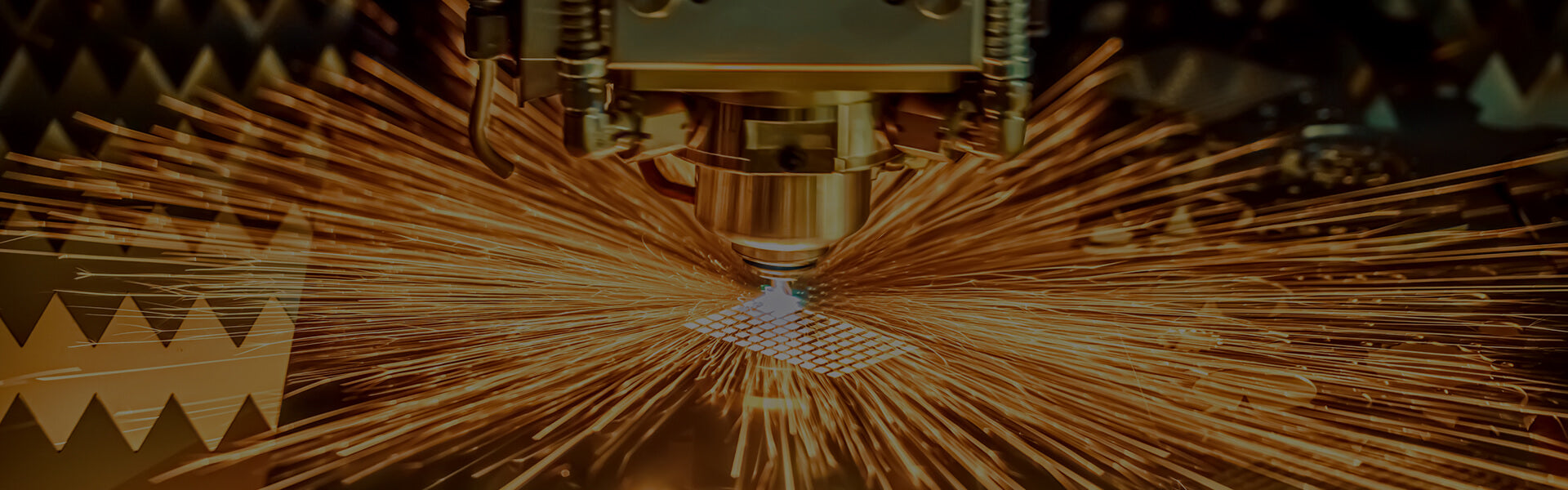

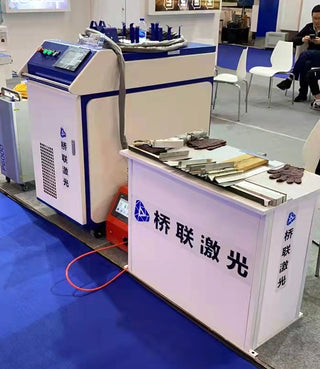

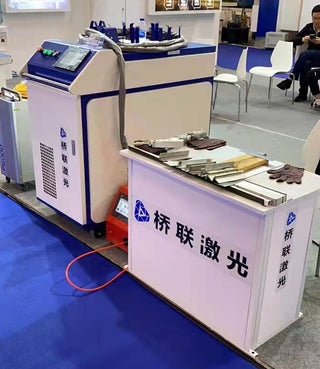

Fiber laser cutting machines in shipbuilding have revolutionized shipbuilding by enabling precise and efficient cutting of thick metal sheets. These machines use advanced laser technology to cut through thick sheets of metal, including steel and aluminum, with remarkable accuracy and speed.

The high-powered fiber laser technology enables precise cuts with minimal heat distortion, reducing the need for expensive rework and decreasing material waste. These machines boast high efficiency rates, allowing shipbuilders to complete projects faster and with more precision than ever before.

Furthermore, the fiber laser cutting machines offer advanced features such as automatic part identification, adaptive cutting, and real-time monitoring, increasing the precision and accuracy of the cutting process. Apart from its many advantages, these machines also offer significant cost savings by eliminating the requirement for traditional cutting techniques that are time-consuming and less precise.

The incorporation of fiber laser cutting machines in shipbuilding has been a game-changer in the industry. These machines offer higher speed, precision, and efficiency, leading to increased productivity and cost savings for shipbuilders.

Overall, fiber laser cutting machines are revolutionizing the shipbuilding industry by providing a faster, more precise, and cost-effective alternative to traditional cutting methods. As shipbuilders continue to adopt these machines, we can expect to see a significant increase in productivity and efficiency in the industry, leading to the production of better quality ships at lower costs.