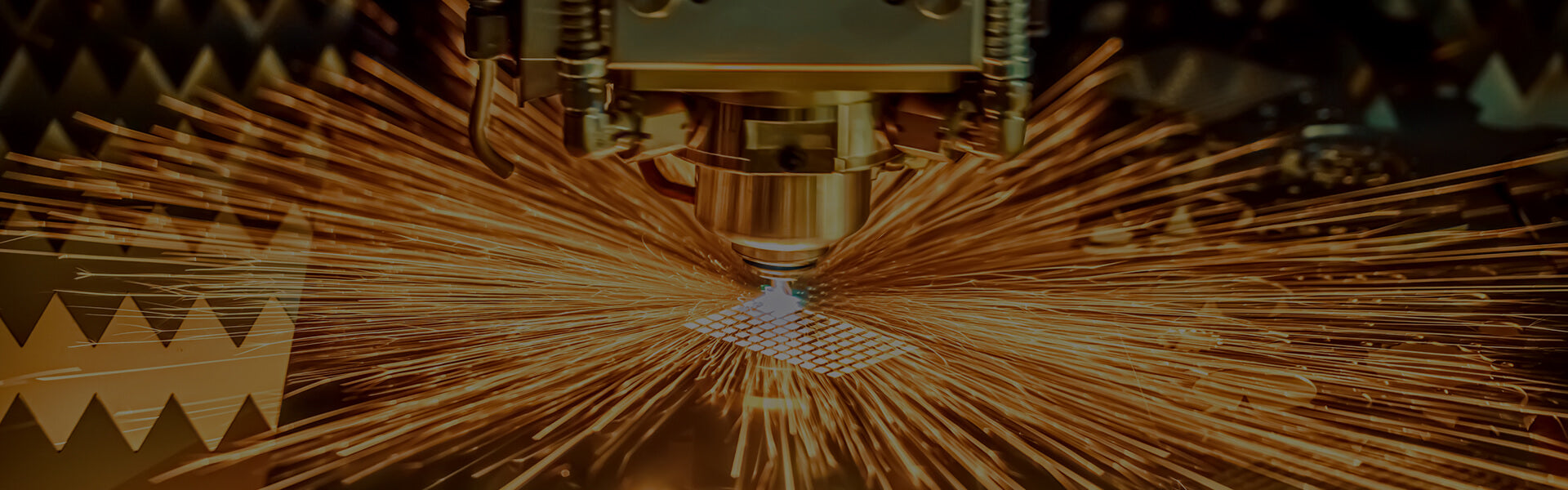

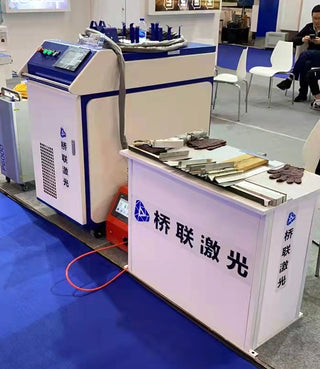

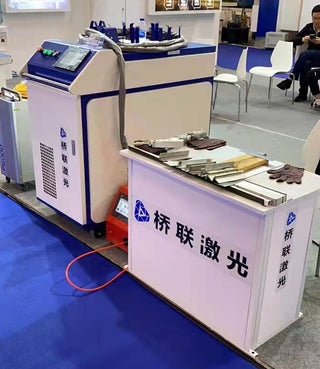

Laser technology has revolutionized many industries, and the automotive sector is no exception. Laser cleaning, cutting, and welding have become increasingly popular in automotive manufacturing and repair. Laser cleaning offers a non-abrasive, effective, and efficient way to remove unwanted coatings, rust, and debris from car surfaces and engine parts. Laser cutting provides precision, speed, and accuracy in fabricating car body and engine parts. Laser welding creates strong, durable, and high-quality welds between different materials used in automotive manufacturing and repair.

The use of laser technology in the automotive industry has several benefits. Laser cleaning, cutting, and welding require minimal setup and preparation time, compared to traditional methods, resulting in increased production efficiency and reduced downtime. Laser technology also offers high precision and accuracy, producing consistent and quality results in every operation. The ability to work on complex shapes and materials that were previously not possible with traditional methods has opened up new possibilities in automotive design and manufacturing.

As the automotive industry continues to evolve, laser technology will undoubtedly play a crucial role in supporting its growth and development. The precision, efficiency, and versatility offered by laser cleaning, cutting, and welding will become increasingly valuable as manufacturers strive to meet the demands of a competitive market. The use of advanced laser technology in the automotive industry serves as a testament to the innovation and progress driving the sector forward towards a cleaner, higher efficiency, and safer future.

In addition, laser technology offers several advantages over traditional methods, including reduced material waste, improved accuracy, and faster processing times. This means that manufacturers can not only improve the quality of their products but also increase their productivity and profitability.

For example, in the automotive industry, laser cutting is used to manufacture complex parts with high precision, while laser welding is used for joining dissimilar metals and creating high-strength bonds. Laser cleaning is also used to remove contaminants from automotive components prior to assembly, improving the reliability and longevity of the final product.

As the automotive industry moves towards electric and autonomous vehicles, laser technology will play an even more critical role in the manufacturing process. These vehicles require advanced materials and precise manufacturing techniques, which can only be achieved with the help of laser technology.

In summary, the use of advanced laser technology in the automotive industry is revolutionizing the way manufacturers approach production. With its precision, efficiency, and versatility, laser technology will continue to drive the industry forward towards a cleaner, higher efficiency, and safer future.