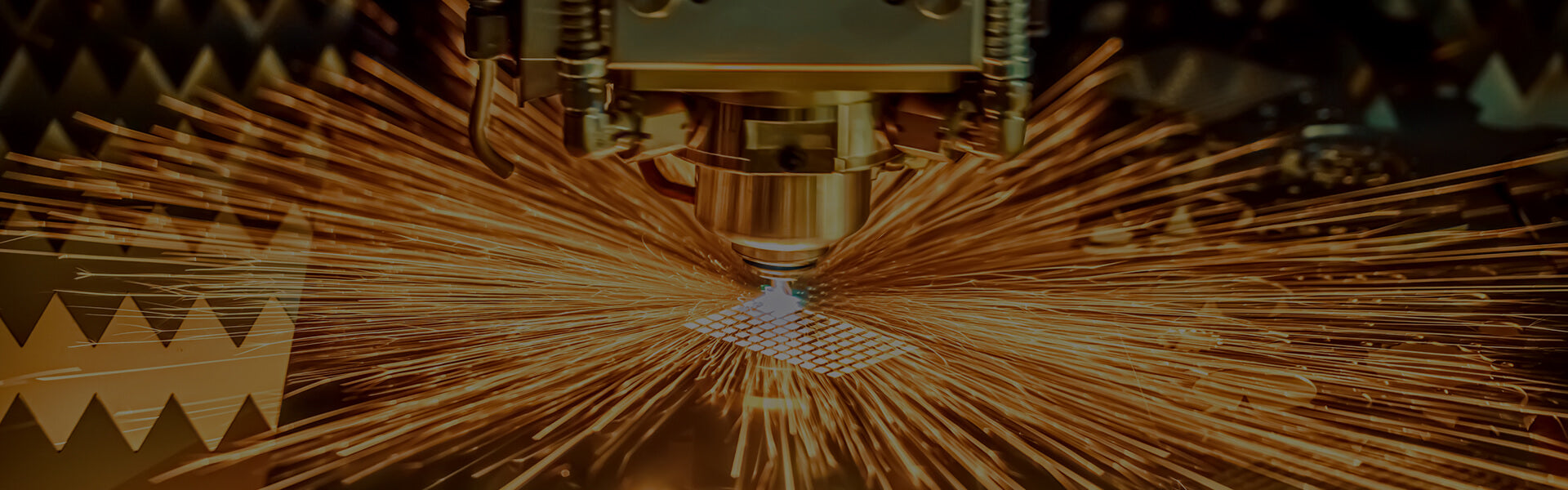

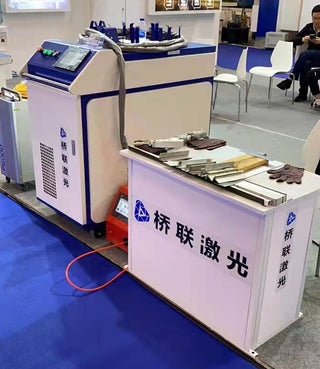

Fiber lasers have revolutionized the metal fabrication industry with their ability to cut and weld materials with a high degree of precision and efficiency. Used in applications ranging from automotive to aerospace to electronics, fiber lasers have become an indispensable tool for metal fabricators around the world.

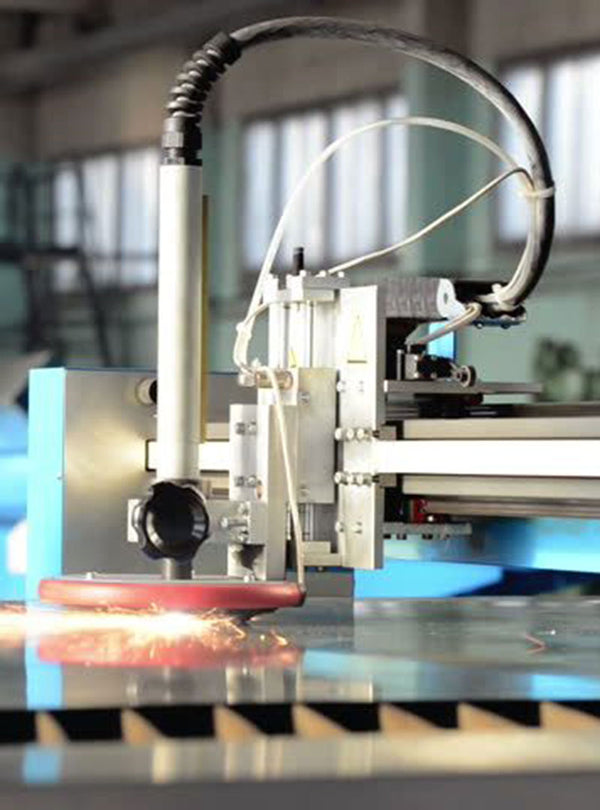

One of the key advantages of fiber lasers is their flexibility. They can be used on a wide range of materials, from thin sheets to thick plates, with a variety of configurations and cutting speeds. In addition, fiber laser technology has advanced to the point where it is now possible to achieve high-quality cuts and welds without damaging the material or leaving behind any residue.

The use of fiber lasers in metal fabrication has also led to increased productivity and cost savings for businesses. With faster cutting speeds and less downtime for maintenance, they have become an essential tool for meeting tight production deadlines and reducing waste.

As the metal fabrication industry continues to evolve, fiber lasers will undoubtedly play an even greater role in shaping its future. With their ability to cut and weld materials with unmatched precision and efficiency, they will continue to be a critical component in the manufacturing process of many industries.