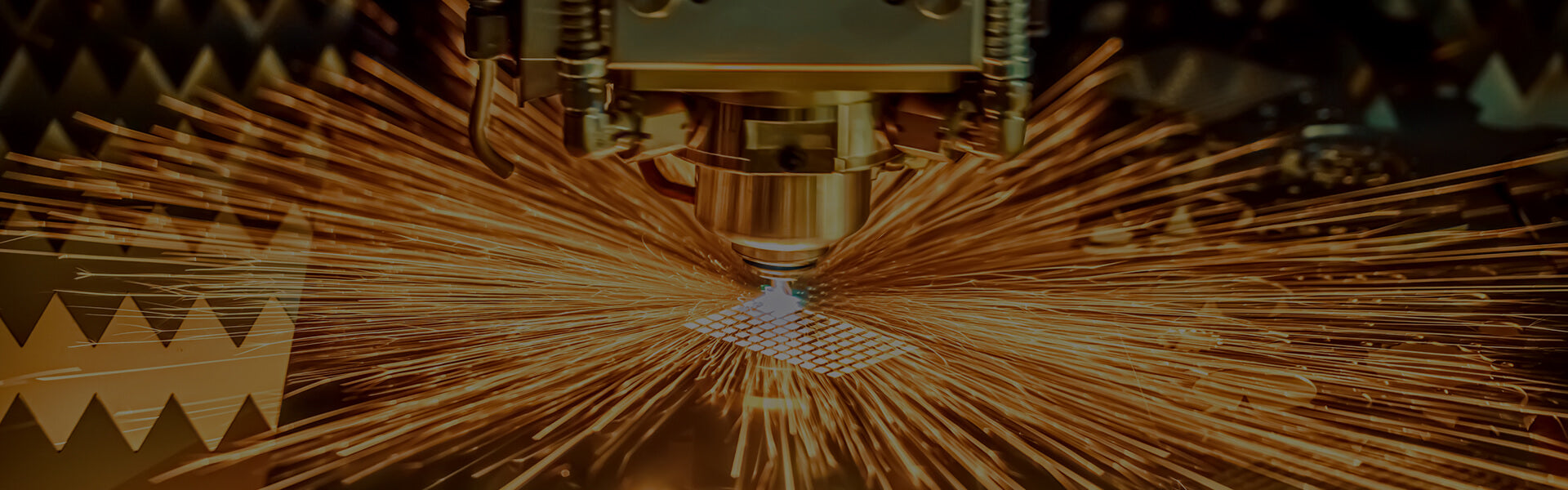

Agricultural machinery manufacturers have turned to laser cutting machines for their precision, speed, and versatility. In the agriculture machinery industry, thin and thick metal parts are commonly used. These parts must be capable of enduring harsh conditions while maintaining precision and durability.

One of the significant advantages of laser cutting for agricultural machinery is the ability to create complex parts in a single operation. This reduces the need for multiple manufacturing steps, ultimately saving time and increasing production efficiency.

Another major benefit is the ability to cut different shapes and sizes of materials cleanly and accurately, leading to seamless integration of machine parts. This precision ensures the longevity and durability of the machinery, resulting in higher customer satisfaction.

Laser cutting machines also have features that allow for customization and personalization of the equipment. Different designs, logos, or other identifying marks can be etched into the machinery, adding a unique touch and branding for individual manufacturers.

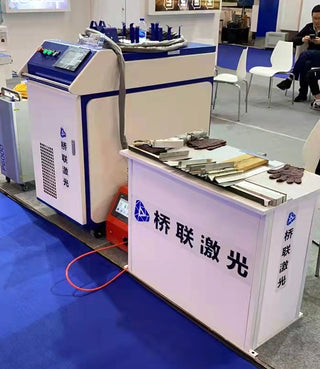

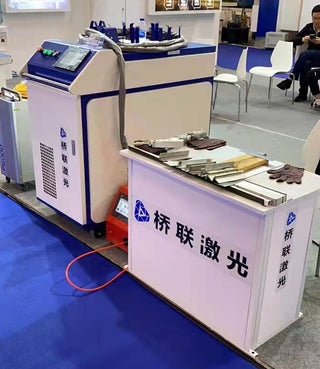

Thanks to Qiaolian Laser machines, it's possible to swiftly cut and weld both small and large sections such as cabin bodies, axles, and lower parts that are essential in various machinery applications - from tractors to axles. By utilizing a high-power laser machine for production purposes , these necessary parts can be manufactured easily. The requisite machine has to be long-lasting, gigantic yet powerful enough so that the agricultural industry can develop extensive machinery without impediments.