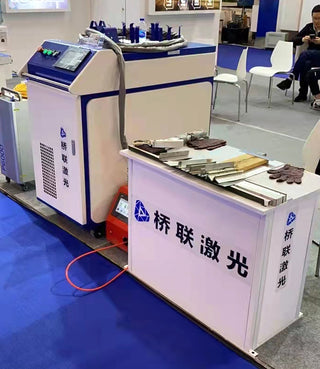

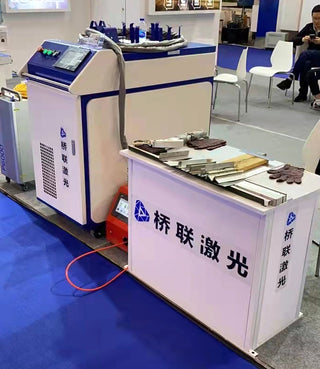

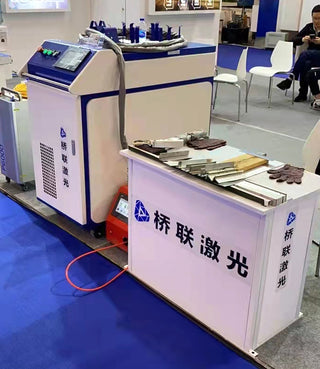

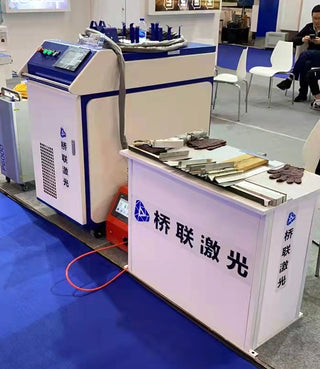

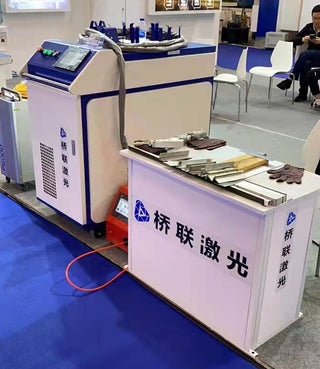

This handheld fiber laser welding machine is perfect for welding any parts and is easy to move. It is equipped with a new dual scan technology that allows our new lightweight pistol to perform many types of welding. Plus, our one-shot weld-to-shape process means there's no distortion, so your product will meet the high quality standards you've come to expect.

It has the advantages of simple operation, stable operation, perfect welding beam and fast welding speed. This machine is suitable for welding metal materials such as thin aluminum sheet, stainless steel sheet, iron sheet, galvanized sheet, etc. It can perfectly replace the traditional, argon arc welding and MIG welding process. High power and fast welding speeds make it an excellent choice for mass production.

The handheld laser welding machine can be widely used in complex and irregular welding processes in cabinets, kitchens, stairs, elevators, storage racks, ovens, stainless steel door and window guardrails, distribution boxes, stainless steel household and other industries.

1000W to 3000W Handheld Fiber Laser Welding Machine Features

1000W to 3000W Handheld Fiber Laser Welding Machine Advantages

Suitable for different scenes with 6 luminous modes.

Light spot is adjustable from 0 to 6 mm.

Directly set the parameters of wire feeder digitally through the control screen, keeping the wire feeding smoothly.

Stainless steel, carbon steel and aluminum wire can be delivered in various (0.8\1.0\1.2\1.6mm) specifications.

Perfect replacement part of the traditional argon arc welding, thin stainless steel plate, iron plate, aluminum plate and other electric welding.

Weld penetration table

| Material | Thickness (mm) |

Wire feed speed (mm/s) |

scan width (mm) |

Power (W) |

wire diameter (mm) |

Max Weld penetration | Using Gas |

| Stainless steel | 1 | 80 | 2.5 | 350 | ER304 1.0 | 90% | Nitrogen/ argon |

| 2 | 80 | 3 | 500 | ER304 1.2 | 100% | ||

| 3 | 70 | 3 | 700 | ER304 1.2 | 100% | ||

| 4 | 65 | 3.5 | 1000 | ER304 1.2 | 100% | ||

| 5 | 60 | 3.5 | 1500 | ER304 1.6 | 100% | ||

| 6 | 60 | 4 | 1600 | ER304 1.6 | 80% | ||

| 7 | 60 | 3.5 | 2000 | ER304 1.6 | 100% | ||

| 8 | 50 | 3.5 | 2800 | ER304 1.6 | 100% | ||

| Carbon steel | 0.5 | 45 | 2.5 | 250 | ER 0.8 | 80% | Nitrogen/ argon/pure air |

| 1 | 80 | 2.5 | 380 | ER 1.0 | 90% | ||

| 2 | 70 | 3 | 700 | ER 1.2 | 100% | ||

| 3 | 65 | 3 | 1200 | ER 1.2 | 100% | ||

| 4 | 60 | 3.5 | 1500 | ER 1.2 | 100% | ||

| 5 | 60 | 3.5 | 1700 | ER 1.6 | 100% | ||

| 6 | 60 | 4 | 2000 | ER 1.6 | 80% | ||

| 7 | 50 | 3.5 | 2600 | ER 1.6 | 100% | ||

| 8 | 45 | 3.5 | 3000 | ER 1.6 | 100% | ||

| Aluminium | 1 | 80 | 2.5 | 450 | AL 1.0 | 90% | Nitrogen/ argon |

| 2 | 70 | 3 | 900 | AL 1.2 | 100% | ||

| 3 | 65 | 3 | 1500 | AL 1.2 | 100% | ||

| 4 | 60 | 3.5 | 1800 | AL 1.2 | 100% | ||

| 5 | 60 | 3.5 | 2200 | AL 1.6 | 100% | ||

| 6 | 55 | 3.5 | 2800 | AL 1.6 | 80% | ||

| Note: 1.Default parameters: scanning speed: 300mm, duty cycle: 100%, pulse frequency: 1000Hz 2.The above gas welding blowing pressure is set between 0.3 MPa and 0.5 MPa by adjusting the pressure regulating valve 3.Suggest gas using Nitrogen, Nitrogen purity:99.99% |

|||||||

Imported Parts, Precision Guaranteed

Welding type:

Fillet welding vertical welding

Tailor welding flat welding

Overlap welding

Samples

Have any questions?Let's get in touch!

Contact us if your are thinking of purchasing highqualityingredients, develop new products, or justsolving a manufacturing challenge in your rawmaterials.