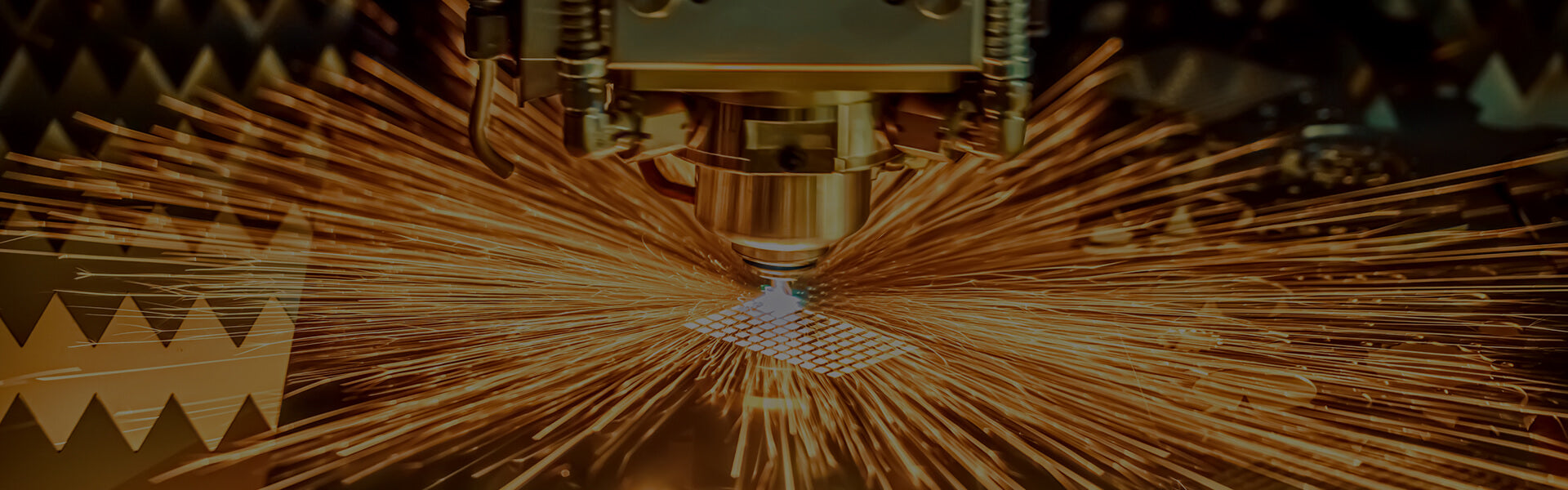

Applications for Fiber Laser Cutting Machine

The advancement in laser technology has led to the growing popularity of fiber laser cutting machines in multiple industries. These machines have become a preferred choice for replacing conventional cutting methods due to their flexibility and versatility. Laser cutting technology is now widespread across metal processing industries because of the high precision and efficiency it provides. The powerful laser beam used by fiber laser cutting machines allows them to effortlessly cut through materials, including metals. Besides traditional applications, these advanced machines have opened up possibilities for various other industries seeking to benefit from their capabilities.

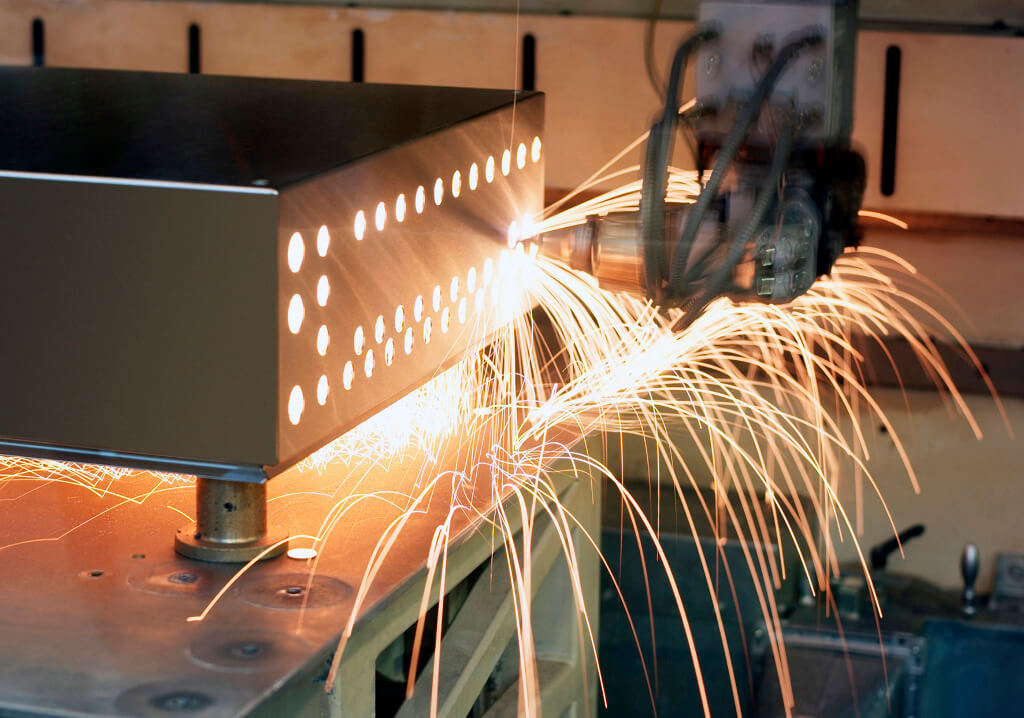

Metal fabrication

Fiber laser cutting machines are commonly used for cutting and shaping metal materials in metal fabrication industries. These machines can cut metal sheets, pipes, tubes, and plates accurately and quickly.

Learn More

Shipbuilding

Fiber laser cutting machines are popular in shipbuilding due to high efficiency and accuracy in cutting metals like steel, aluminum, and titanium. Benefits include high-speed and precise cutting, lower operating costs and maintenance, and versatility for various applications.

Learn More

Agricultural Machinery

As agriculture continues to evolve, agricultural machinery products are becoming increasingly specialized and diverse. Laser cutting machines have played a crucial role in meeting these challenges by providing precise and efficient customization for everything from advanced tractors to simple irrigation equipment.

Learn More

Fitness Equipment Iindustry

The diversity of fitness equipment also puts forward higher requirements for processing. Traditional cutting machines are aimed at products with various specifications and shapes, and the processing is complicated and the efficiency is low. Laser cutting has high flexibility and can be customized and flexible for different pipes and plates. The finished product is smooth and burr-free, without secondary processing, and the quality and efficiency are greatly improved.

Learn More

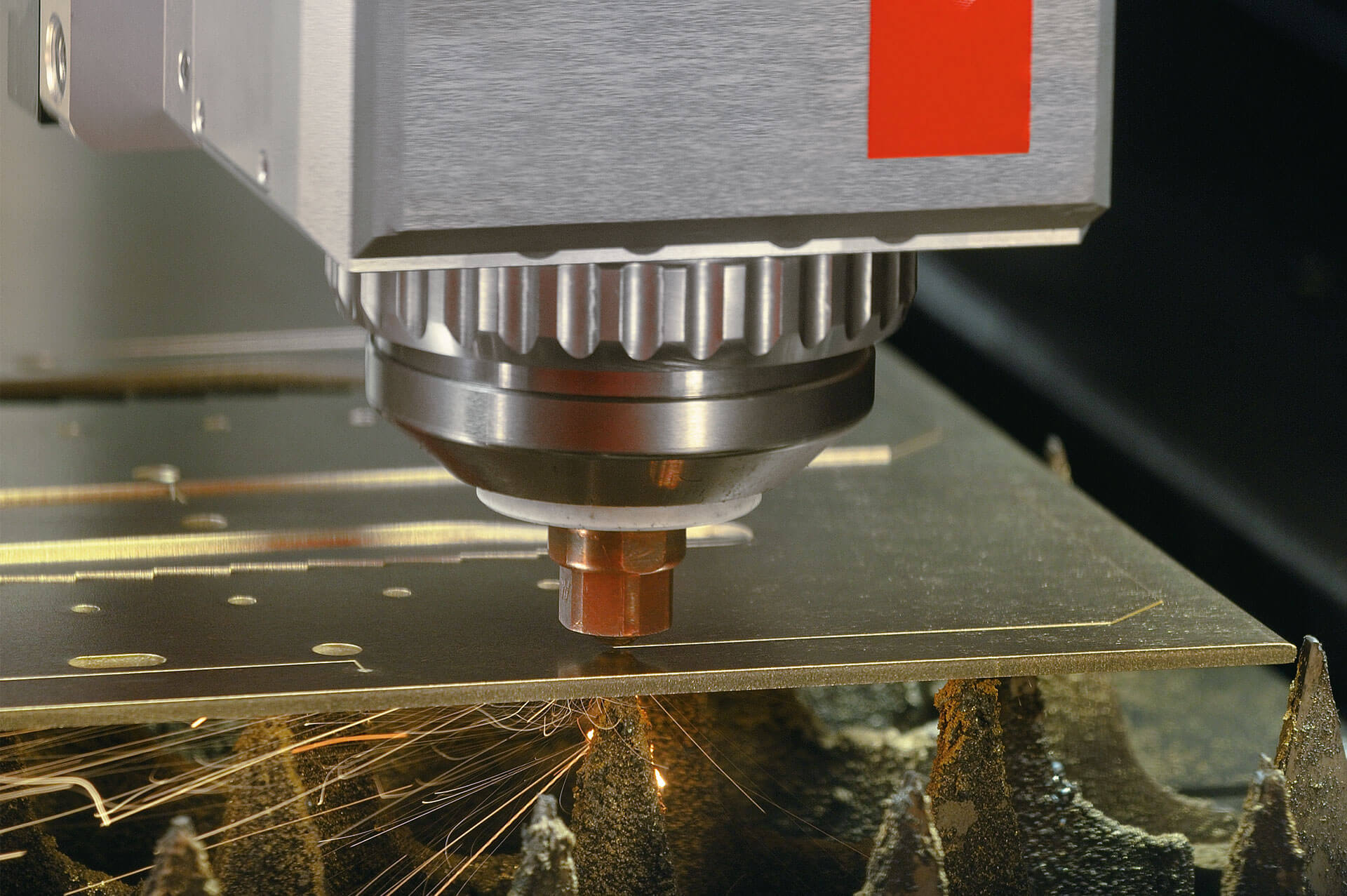

Automobile Manufacturing

There are many precision parts materials in automobiles, such as automobile brake pads. In order to improve the safety of automobiles, it is necessary to ensure the cutting accuracy. Laser cutting provides accurate shapes and quicker processing, making it popular among manufacturers for its efficiency and quality.

Learn More

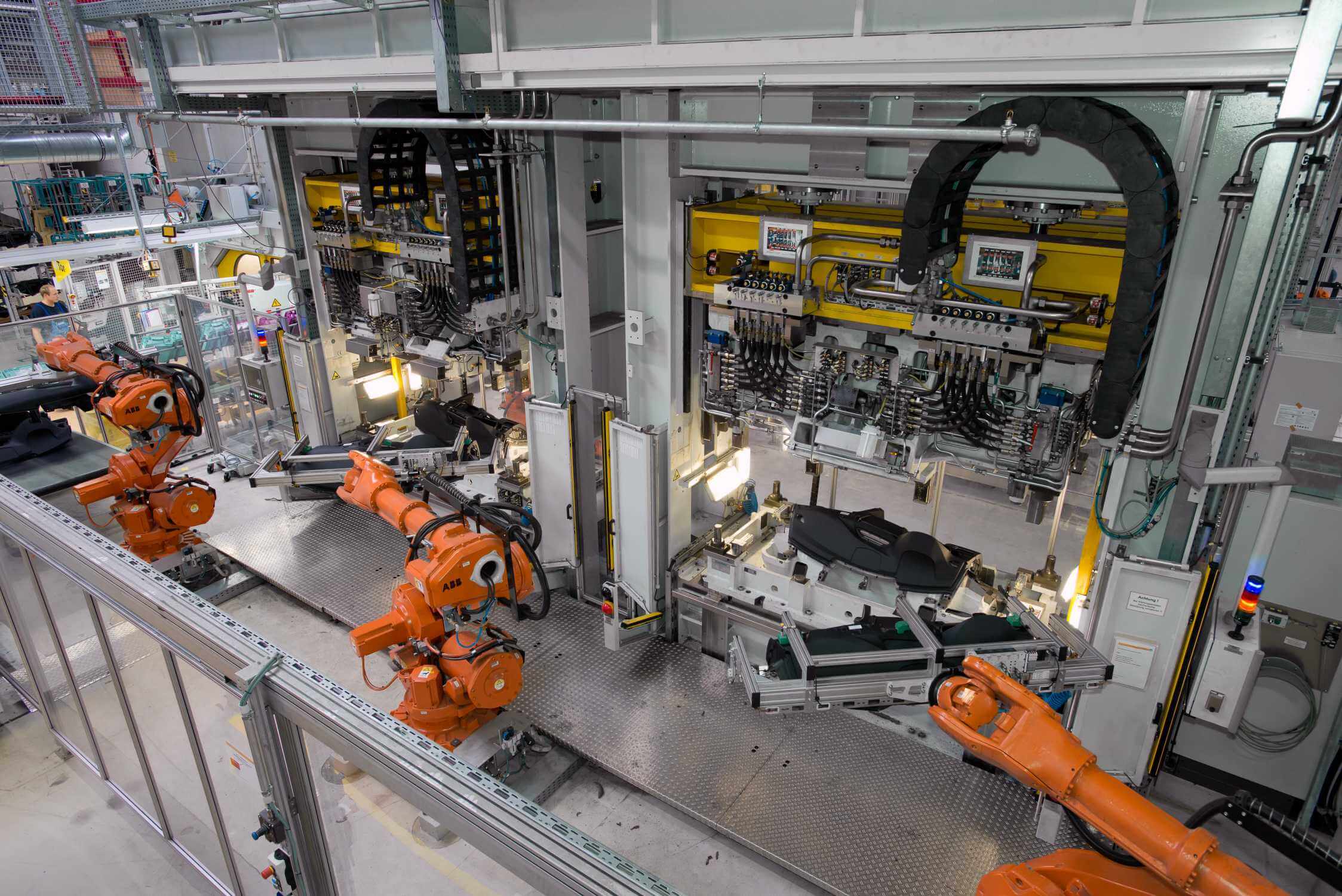

Aerospace

Fiber laser cutting machines are used in the aerospace industry to cut and shape metal components, such as airplane wings and fuselages. These machines can also cut composite materials used in the aerospace industry.

Learn MoreHave any questions? Let's get in touch!

Contact us if your are thinking of purchasing highqualityingredients, develop new products, or justsolving a manufacturing challenge in your rawmaterials.