The advantage of handheld fiber laser cleaners is their environmental friendliness. Unlike traditional cleaning methods that use chemicals and generate hazardous waste, laser cleaners are environmentally friendly, do not generate hazardous waste, and do not emit harmful chemicals into the atmosphere. Its compact and lightweight design makes it easy to use and transport.

Handheld fiber laser cleaning machines are also very versatile and can be widely used in automotive, aerospace, electronics, manufacturing and other industries. They can be used to clean various components such as engine blocks, molds and production equipment.

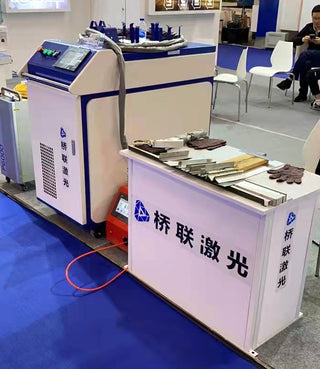

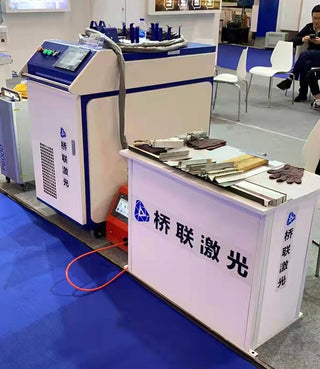

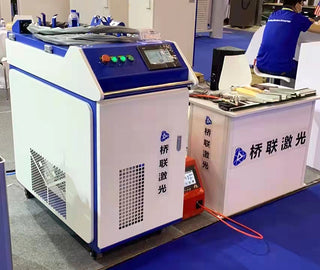

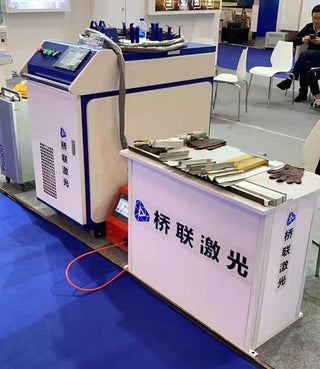

1500W to 3000W handheld fiber laser cleaning machine features

High Power Output

The handheld fiber laser cleaner's 1500W to 3000W power output enables it to quickly and efficiently remove even the most stubborn contaminants, making it ideal for large-scale industrial applications.

Handheld Design

The machine's handheld design makes it easy to use and operate, even in hard-to-reach areas, providing a convenient and flexible cleaning solution.

Versatility

The machine can clean a variety of materials including mild steel ,stainless steel, aluminium,copper etc.making it suitable for a wide range of industries including automotive, aerospace, electronics and manufacturing.

Non-contact Cleaning

This machine adopts non-contact cleaning method, which will not damage the surface to be cleaned, and is very suitable for cleaning precision parts and materials.

Eco-Friendly

Unlike traditional cleaning methods that use chemicals and generate hazardous waste, laser cleaners are environmentally friendly and do not generate hazardous waste nor emit harmful chemicals into the atmosphere.

Low Maintenance

With low maintenance requirements and no consumables, this machine is a cost-effective and hassle-free cleaning solution.

High Precision

The machine can target specific areas for precise cleaning, reducing the need for rework and minimizing the risk of damaging the material being cleaned.

Have any questions?Let's get in touch!

Contact us if your are thinking of purchasing highqualityingredients, develop new products, or justsolving a manufacturing challenge in your rawmaterials.